Products

-

Adjustable Base Jack

-

Adjustable U Head Jack

-

Adjustable Universal Jack

-

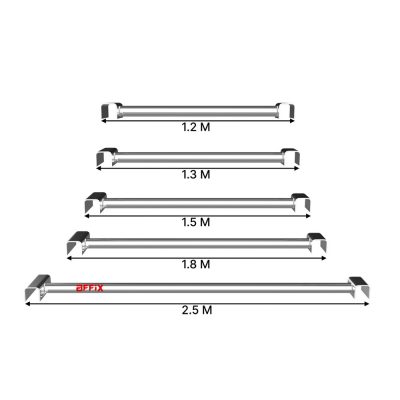

Aluminium Beam-Double Web Heavy

-

Aluminium Beam-Single Web Heavy

-

Aluminium Beam-Single Web Light

-

Aluminium Lattice beam

-

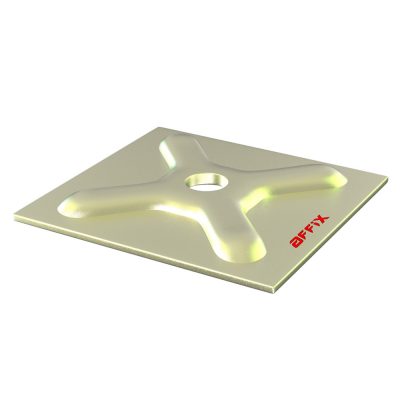

Base Plate

-

Beam Bracket

-

Board Retaining Coupler

-

Cantilever Frame

-

Castor Wheels

-

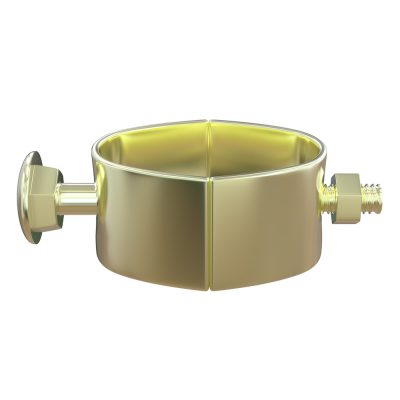

Cuplock Intermediate Transom

-

Cuplock Ledger

-

Cuplock Spigot Pin

-

Cuplock Standard

-

Cuplock Swivel Face Braces

-

Double Cantilever Frame

-

Double Coupler

-

Fork U-Head Jack

-

Galvanized Pipe

-

Girder Coupler

-

H Frames

-

H20 Beams

-

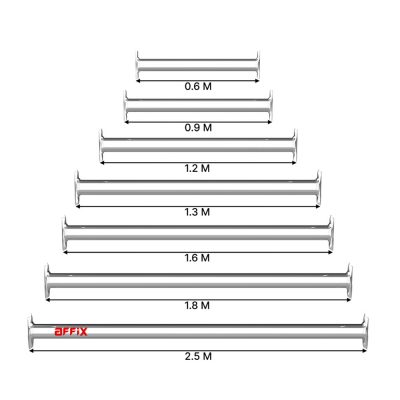

Ladder Beam

-

Ladder Clamp

-

Pressed Sleeve Coupler

-

Prop Jacks

-

Push Pull Prop

-

Single Coupler

-

Staircase Unit

-

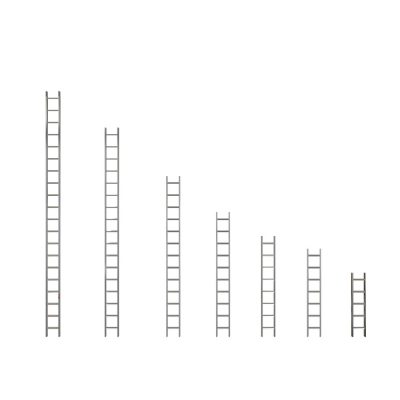

Steel Ladder

-

Steel Planks

-

Swivel Adjustable Base Jack

-

Swivel Coupler

-

Tie Rods

-

Toe Board Clamp

-

Universal Clamps

-

Waller Plate

-

Water Barrier Nut

-

Wing Nut

-

Wooden Planks

Applications

Cuplock System Scaffolding for Sale in Qatar

Scaffolding is a kind of temporary stage or structure commonly used in the construction industry to help workers safely perform construction work at heights. Seeing its usefulness and significance, scaffolds must be strong and sturdy, they may result in fatal injuries.

Among the different types of scaffolding available Cuplock scaffolding system is a highly popular scaffolding system. It is a modular scaffolding system comprising pre-engineered horizontal and vertical components that are aligned in a systematic manner to provide construction workers with a temporary structure that proves extremely useful for completing complex construction projects.

Affix Scaffolding is a leading manufacturer and supplier offering a wide array of working platforms and edge protection systems in the Gulf region. Construction businesses looking for a top-quality new or used Cuplock scaffolding system can order it from Affix.

Benefits of the Cuplock Scaffolding System

The Cuplock scaffolding system is highly used all over the world because of its unique locking mechanism. Since this scaffolding system connects through a unique circular node locking design, it provides greater flexibility and safety to users. This scaffolding system is easy and quick to set up and is highly economical.

Cuplock scaffolding is a fully galvanized system that is immensely popular and is widely chosen by constructors and builders to execute the most complex projects. Some of the major benefits of this scaffolding system include:

- Saves Cost and Time: This scaffolding system features adaptable components so it can be easily set up for diverse purposes such as maintenance, refurbishment, and construction. Traditional scaffolding systems took a long time to assemble,e whereas Cuplock scaffolding, ng with more adaptable and flexible components,nts is quick and easy to assemble. Thus, companies can quickly set up scaffolding at work sites, helping workers get to their tasks faster. By saving time, the company is able to save costs as its team is able to quickly complete projects.

- Light and Safe: Cuplock scaffolding system is usually made with lighter and palletized materials, so it is easier for workers to transport them. Since this scaffolding system features a galvanized surface,o the Cuplock scaffolding tubes are much more durable and are lighter than traditional tubes. Besides, Cuplock scaffolding better resists corrosion from weather conditions. In addition to being light in weight, this scaffolding is also much safer compared to traditional scaffolding. It is free of diagonal bracing obstruction that was common in traditional scaffolding, which makes this work platform safer to navigate.

- Easy to Install and Safe Locking Procedure: The most significant feature of this scaffolding system is its node-point locking device, where a single vertical tube connects with four horizontal tubes. Besides, this system does not require any loose bolts, wedges, or clips to lock components to the node-point, making this scaffolding easier and faster to install.

Features ofthe Cuplock Scaffolding System

Cuplock scaffolding system is a highly valuable and vital temporary platform that makes sure construction work is safe and easy, so that workers are allowed to build the best. It is a temporary network of frames that support workers during the construction or renovation of a structure where workers need to access high points.

It is highly preferred for construction projects where a large scaffolding system needs to be quickly installed to support a relatively heavy load. This scaffolding system provides walkways to workers that they use to access several areas of the construction site that are notnormally accessibley. The design of this scaffolding is such that it reduces the assembly time while providing a safe, strong, and versatile structure to construction workers.

Some of the distinguishing features of the Cuplock scaffolding system include:

This scaffolding is usually available in component form that can be easily assembled at the construction site.

The bars and fixtures of scaffolding are made from galvanized metal and have a protective coating that makes the scaffolding weather-resistant. It is resistant to rust and corrosion, making it ideal for large-scale outdoor projects.

It is safe, reliable, cost-effective, and versatile scaffolding used widely for diverse applications.

The strong, durable, and easy-to-handle scaffolding meets local and federal regulatory requireme soence it is safe to use.

This scaffolding is easy-to-install and requires minimal maintenance and storage space.

Components of the Cuplock Scaffolding System

Cuplock scaffolding comprises various parts and components that are required for the installation of the Cuplock structures. Some of the key components of the Cuplock scaffolding system include:

- Cuplock Standard

- Cuplock Ledger

- Cuplock Intermediate Transom

- Cuplock Swivel Face Braces

- Cantilever Frame

- Double Cantilever Frame

- Beam Bracket

- Cuplock Spigot Pin

- Adjustable Base Jack

- Adjustable Universal Jack

- Swivel Adjustable Base Jack

- Fork U-Head Jack –

- Double Coupler

- Base Plate

- Swivel Coupler

- Single Coupler

- Girder Coupler

- Board Retaining Coupler

- Pressed Sleeve Coupler

- Ladder Clamp

- Toe Board Clamp

Different Types of Cuplock Scaffolding Application

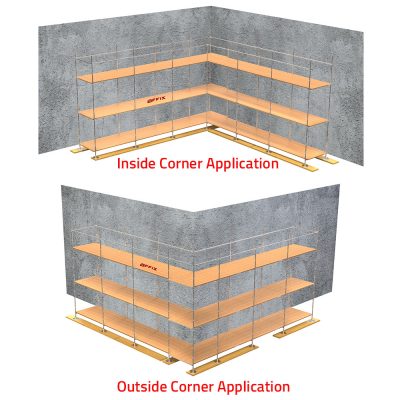

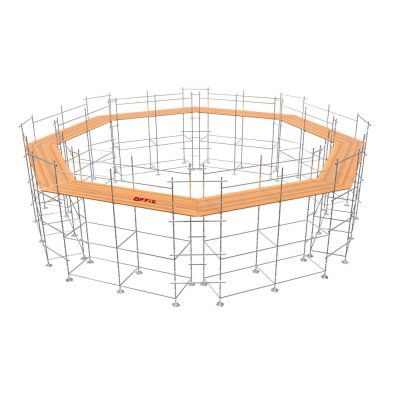

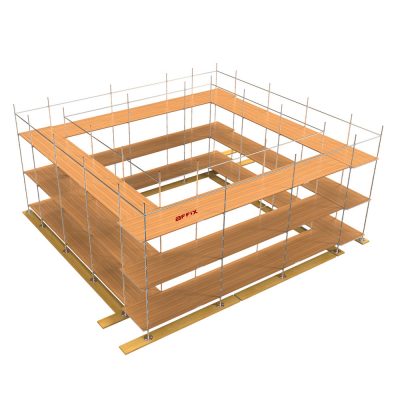

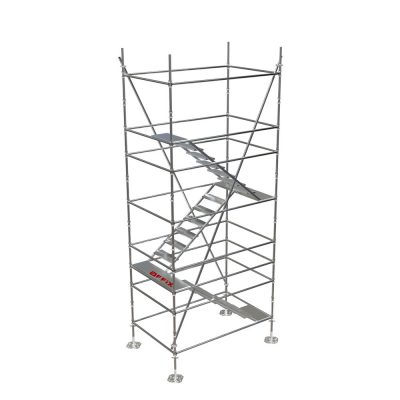

Affix Scaffolding is a leading manufacturer and supplier of a wide range of new Cuplock scaffolding that can be used for diverse applications at construction sites. Used Cuplock scaffolding system is also available for sale in our store. The Cuplock scaffolding is ideal for a wide range of applications, such as corner applications, mobile applications, circular applications, square or rectangular applications, or staircase towers.

Due to the versatility of Cuplock scaffolding, it is best suited for framework support and is extremely durable to be used on construction sitesand workk with a variety of support structures. It is composed of pre-engineered horizontal and vertical parts that are joined in a specific order to make it easy to use for a variety of applications. It is extremely durable to be used in the construction sector, and it is used with a variety of support structures. This scaffolding is immensely used for the construction of dams, tunnels, houses, bridges, chimneys, and is also used in demolition and maintenance projects for straight as well as curved structures. It is also used for the construction of overpasses and railway viaducts.

Why choose Affix Scaffolding for Cuplock Scaffolding in Qatar?

With so many Cuplock scaffolding manufacturers available in Qatar, customers do have a good choice of options. However, as far as picking the best quality Cuplock scaffolding in Qatar is concerned, Affix Scaffolding turns out to be the best choice because of the following reasons:

Affix offers lightweight Cuplock scaffolding that is easy to install. It is ideal for small projects as it does not require fasteners to assemble it.

Cuplock scaffolding offered by us is easy-to-handle, requires less storage space, and has a high load-bearing capacity.

Our Cuplock scaffolding can be used to create a wide range of access and support structures, such as circular scaffolds, loading towers, etc.

Our scaffolding is a multi-purpose system that is ideal for access and support in different building & civil engineering projects.

We manufacture this scaffolding keeping in mind the safety aspects and have strict quality control measures in place.

Frequently Asked Questions

1. What makes the Cuplock system different from traditional scaffolding?

The Cuplock system uses a fixed bottom cup and a rotating top cup to secure ledgers without separate clamps. This design accelerates assembly, improves joint rigidity, and reduces loose components, enhancing structural stability and job site efficiency.

2. Is cuplock scaffolding suitable for high-rise projects?

Yes. Engineers configure it with proper bracing and base support for elevated structures. Load calculations and stabilizing components ensure safety and compliance for high-rise construction.

3. How do I inspect used cuplock scaffolding?

Inspect standards for bending, examine cup locking mechanisms for wear, check ledger blade condition, and review corrosion levels. Confirm load rating compliance before deployment.

4. What industries use cup lock system scaffolding?

Construction, oil and gas, power generation, marine projects, infrastructure development, and maintenance operations widely use this system due to its strength and adaptability.

5. Does the system require special tools for assembly?

No. The locking mechanism allows quick assembly with minimal tools. Workers secure ledgers by rotating the top cup into position.

6. What materials are commonly used?

Manufacturers typically use galvanized steel to ensure durability, corrosion resistance, and long service life in harsh environments.

7. Can cuplock scaffolding handle heavy loads?

Yes. Properly configured systems support significant loads, provided engineers follow rated capacities and structural guidelines.

8. How do I choose reliable cuplock scaffolding suppliers?

Evaluate product quality, compliance certification, manufacturing standards, supply capacity, and technical support before making procurement decisions.

9. What are the common applications in Qatar?

Applications include façade access, slab support, industrial maintenance platforms, bridge construction, and plant shutdown projects.

10. Is modular expansion possible?

Yes. Contractors extend vertical height and platform levels.